ROADSKY type pavement marking retroreflectometer (retroreflectometer for road markings) is a portable on-site measuring instrument, used for measuring the retroreflection characteristic of road marking. ROADSKY type instrument is to simulate the brightness of road marking that can be seen by the driver under the illumination of motor vehicles at night, and the measured parameter is the coefficient of retrorefection brightness at night, namely, RL value.

Specifications:

| Measurement items: | retroreflective coefficient mcd.m-2.lx-1 |

| Measurement range: | 0—4000 |

| Observation angle: | 1.05° |

| Angle of incidence: | 88.76°, Complementary angle is 1.24° |

| Light source color temperature: | 2856±50K |

| Measuring aperture area: | 340mm x 95mm |

| Error of repeatability measurement: | ≤3% |

| Continuous working time of battery: | >72h |

| Data storage space: | 8GB |

| Built-in battery capacity: | 13Ah |

| Charger: | DC 8.4V |

| Ambient temperature: | -15℃~+60℃ |

| Ambient humidity: | <98%, no frost |

| Instrument size: | 700mm x 135mm x 115mm |

Designed with high precision and high stability structure, ROADSKY type pavement marking retroreflectometer applies high-standard MCU master module, large-capacity storage unit, touch screen display with handwriting input function and embedded program control software, supports for rapid inspection and prints out results on site through the built-in printer. It is featured by free preheating, small measurement error, out-of-the-box and so on. This is a necessary instrument for the production, quality supervision, engineering construction, supervision and other units to measure the retroreflection performance of road marking.

Working Principle

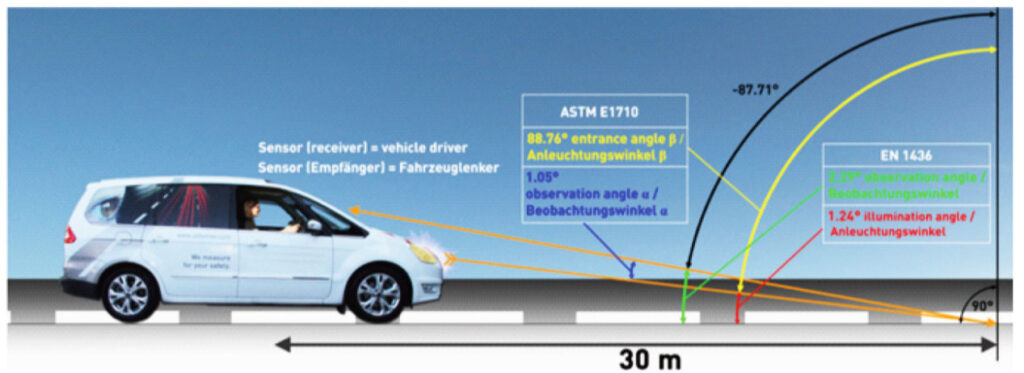

The geometric condition of ROADSKY type pavement marking retroreflectometer is to simulate the brightness that the driver observes in the cab reflected from the marking made of retroreflective material on the road by the headlamp when the vehicle is driven on the road at night. The schematic diagram of the optical path is shown in Fig. 2.

The angle between the optical axis of the headlamp and the normal line (reference axis) of the road surface is called the incidence angle, which is set at 88.76° and the angle between the optical axis of the headlamp and the reflected light is called the observation angle, which is set at 1.05°. The light source of the optical system is directed to the marking line according to the incident angle. The size of measurement window is 340 x 95mm. The reflected light from the marking line is received by the V(λ) filter at the observation angle of 1.05°. After signal processing and calculation, the measured value is displayed. This value is the value of retroreflection coefficient RL.

【Attention】

- This instrument realizes Vλ spectrum correction through advanced optical filter.

- Stray light occasionally enters the instrument, which, however, it will not affect the ongoing normal measurement. Before each measurement and calibration, will automatically evaluate the stray light and automatically generate compensation. In case of significant leakage of the stray light, a detection error message will be provided by the instrument and some protective measures must be taken.

- Light leakage, light drift and offset error of the instrument will be compensated according to the data obtained from calibration procedure. Therefore, it is important to ensure that the calibration board is clean and calibration shall be made regularly.

Main Components of Products

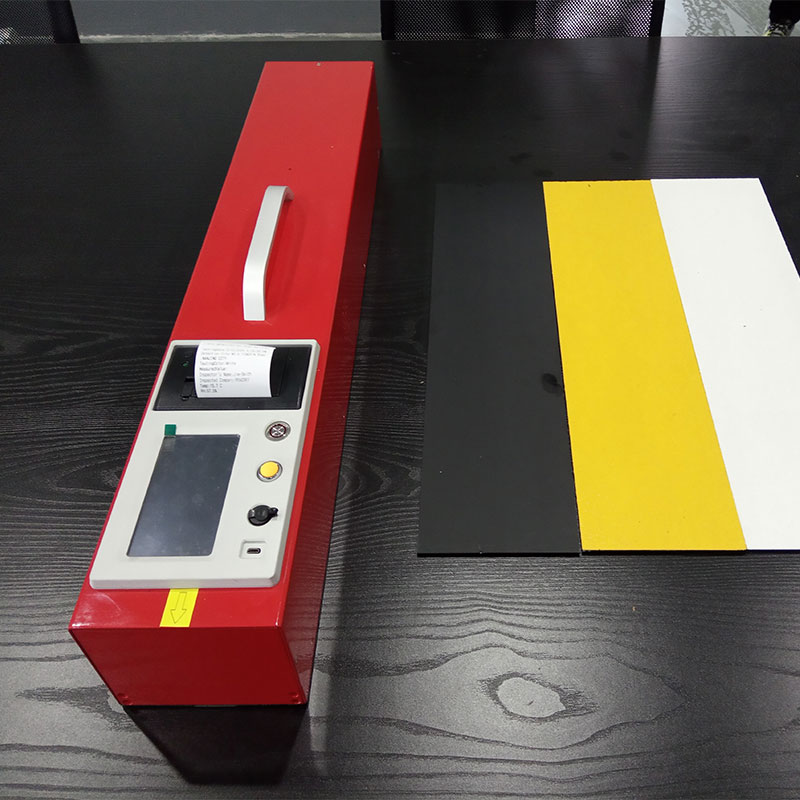

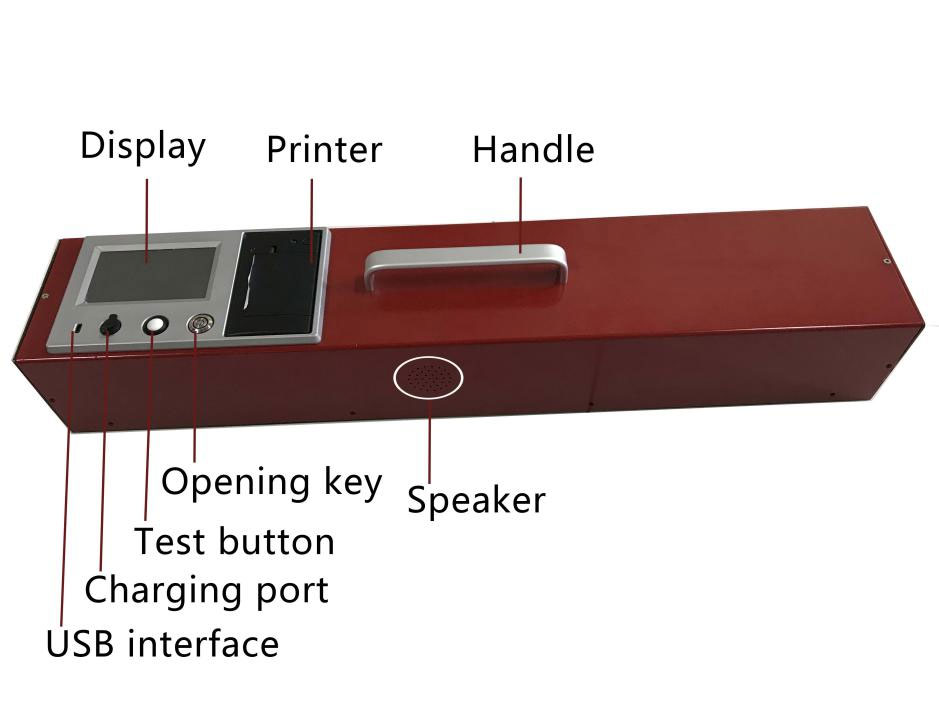

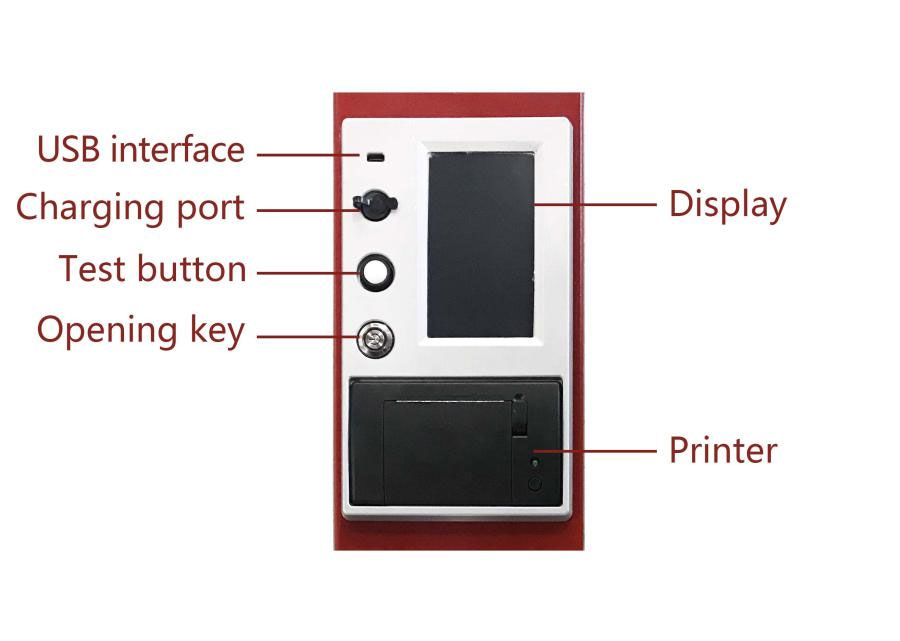

The main components and structure appearance of the instrument is shown in Fig. 3&4, mainly including 3 parts: operation panel, instrument casing and handle, bottom optical detection system.

Matters Needing Attention:

- Read the user manual before using the instrument and please follow the instructions.

- The instrument should be protected from moisture, water and shock. It is forbidden to use the instrument in any harsh environment, such as heavy rain or freezing.

- This product is an optical instrument. When using the instrument, please pay attention to the protection window at the bottom of the instrument, which should not be damaged. If damaged, it will directly affect the measurement results.

- When measuring the data, keep the optical testing window of the instrument close to the surface of the object to be tested, and click the testing button to complete the data collection.

- Turn off the power if it’s not in use.

- Please only use approved special accessories. Do not connect it to incompatible products.

- When the instrument is not in use, it should be placed in a cool and dry place where there is no corrosive gas in the surrounding area.

- If there are quality problems, the instrument can be returned to the factory for repair and calibration. Our factory is not responsible for the instrument which is disassembled by users without our consent.