Thermoplastic road marking paint is widely used in highway and street construction. White and yellow are the most common colors used in thermoplastic marking projects.

Roadsky is the leading thermoplastic road marking paint manufacturer and supplier in China. Both white and yellow thermoplastic road marking paints are renowned for strict quality control and competitive prices. Paint in different standards and colors is also available to meet the different construction needs.

Specification:

| Gravity (g/m³) | 2.1g/m³ |

| Colar | Yellow, Orange, Red and etc |

| Heating Temperature | 150℃-220℃ |

| Softening Point(℃) | 110℃ |

| Coating Appearance | No wrinkles, dots, blisters, cracks, fall-out & stick tyres |

| Drying Time (min) | Within 3 minutes |

| Chroma Performance | Reverse material (white) |

| Compressive Strength (MPa) | 26 |

| Abrasive Resistance (mg) | 42 |

| Water Resistance | Great (in water for 24 hours) |

| Alkali Resistance | Great (in saturated solution of calcium hydroxide for 24 hours) |

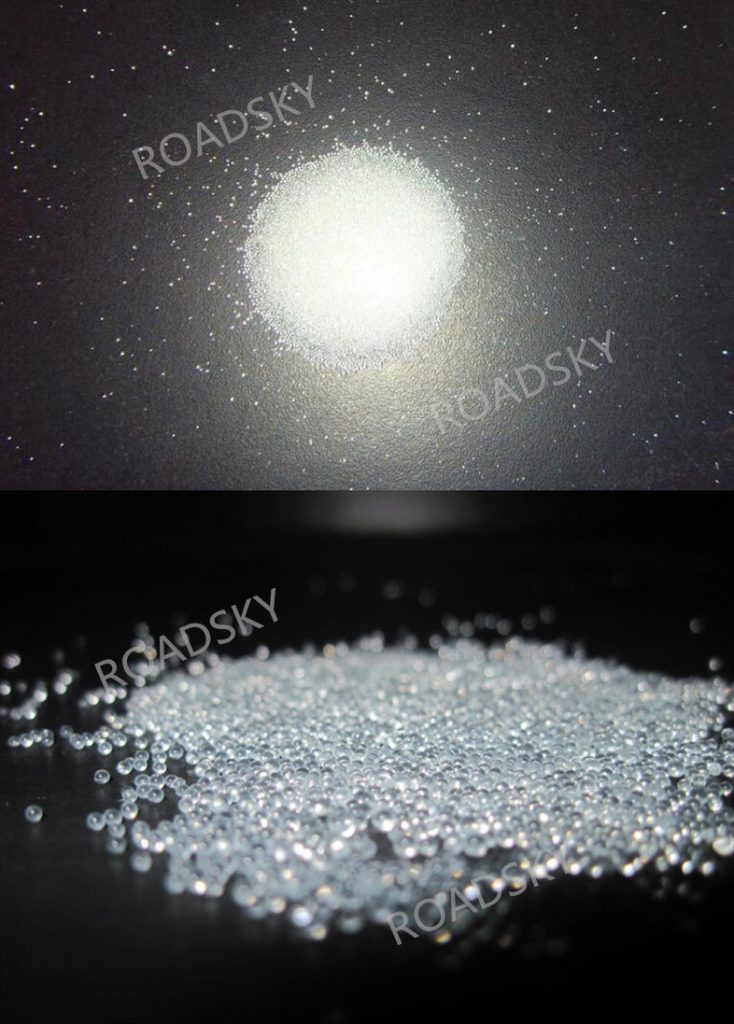

| Glass Beads (%) | 19% |

| Fluidity (s) | 40s |

| Coating Resistance | Resis -10℃ for 4 hours |

| Heat Resistance | Under 200℃-220℃ for hours |

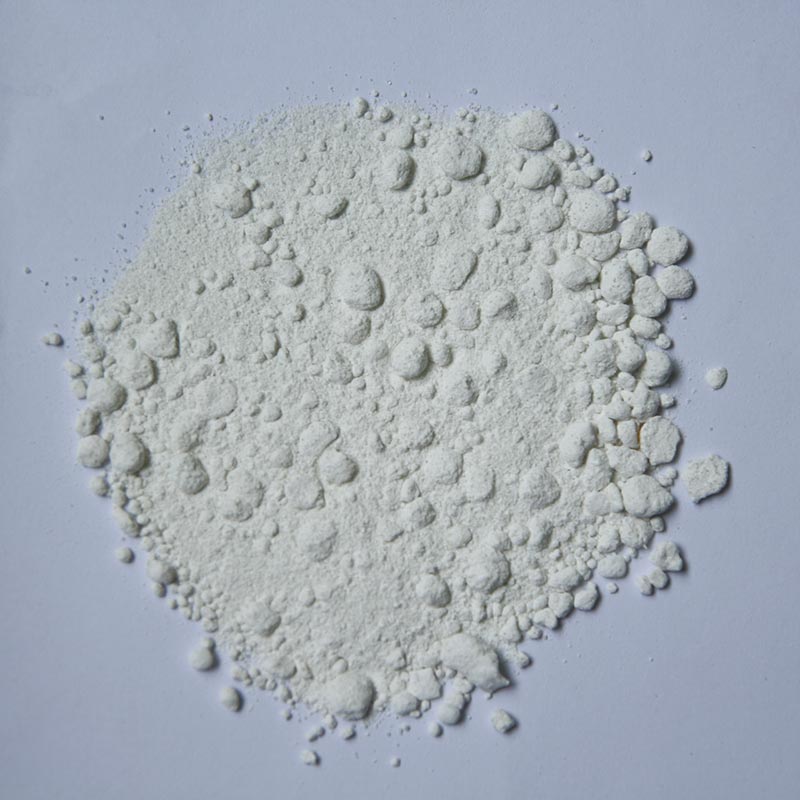

| Material | C5 Petroleum Resin, CACO3, Wax, Glass Beads, EVA, PE and so on. |

| Package | 25kg/bag, by plastic woven bag. One 20’container can load Max. 25 tons |

| Application | Road marking, straight line, dotted line, curve, oriented arrow, letter and etc |

Different Standards:

| AASHTO Standard | ||

| Components | Specification | Test Result |

| Resin | ≥20% | 22% |

| Titanium Dioxide | ≥10% | 10.20% |

| Glass Beads | ≥30% | 32% |

| British Standard | ||

| Components | Specification | Test Result |

| Resin | ≥20% | 21% |

| Titanium Dioxide | ≥10% | 12% |

| Glass Beads | ≥20% | 21% |

| China Standard | ||

| Components | Specification | Test Result |

| Resin | ≥15% | 16.10% |

| Titanium Dioxide | ≥5% | 8% |

| Glass Beads | ≥20% | 22% |

Production and Test of the Paint:

Other Colors:

FAQs

Thermoplastic road marking paint is mainly composed of synthetic resins, glass beads, pigments, and fillers. These components give it durability, color stability, and reflectivity. When heated, the material melts and bonds firmly to the road surface.

The lifespan of thermoplastic markings typically ranges from 3 to 5 years, depending on traffic conditions, weather, and surface preparation. Highways with heavy traffic may require reapplication sooner, while low-traffic areas can last longer.

Thermoplastic paint is more durable, reflective, and cost-effective in the long term. Although it requires heating equipment, it forms a thicker, longer-lasting layer that withstands heavy traffic and extreme weather conditions.

Yes. Thermoplastic paint adheres well to both asphalt and concrete surfaces, but concrete surfaces require primer treatment before application to ensure strong bonding.

The most common colors are white and yellow, used for lane lines and edge markings. Other colors like red, blue, and green are available for special applications such as bus lanes, bike paths, or parking zones.

The typical thickness is 1.5 to 3 millimeters, depending on project requirements. Thicker lines are usually used for highways and pedestrian crossings to enhance durability and visibility.

Contact Us for a Free Quote

Fill The Form Below, and our sales representatives will be in touch with you shortly.