BASIC INFO

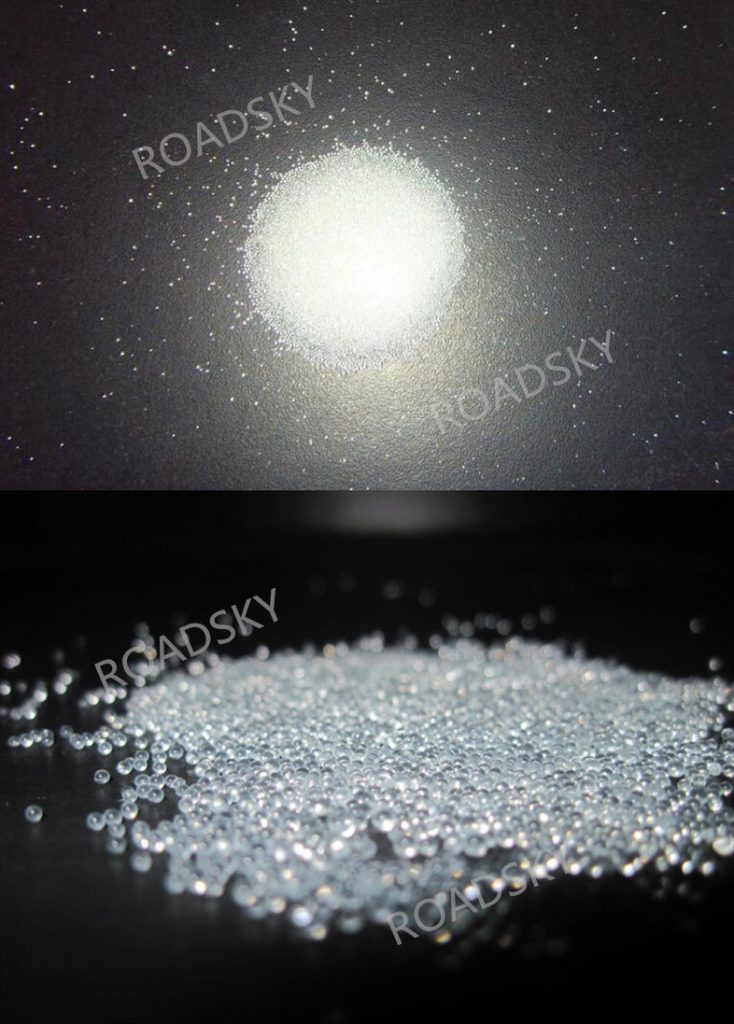

Glass beads Granules are a crucial component of road marking materials, especially thermoplastic and paint-based markings. They enhance the visibility and retro-reflectivity of road markings, making them more effective in guiding drivers, particularly at night or in low-light conditions.

Specifications:

|

Specific gravity(g/cm3 | 2.6g/cm3 |

| Refractive index | 1.5-1.6 |

| Spherical beads(%) | 85% |

| Contents lime glassSiO2 | 72% |

We can manufacture all standards including BS6088A, BS6088B, AASHTOM247, EN1423, EN1424, Australia AS2009 B3.2, KOREA KS standard and Chinese standard and so on.

Test Results of Different Standards

| Type | Size (μm) | Percentage(%) |

|---|---|---|

| BS6088A (intermix) | >1180 | 0~3 |

| 1180~850 | 5~20 | |

| 850~425 | 65~95 | |

| <425 | 0~10 | |

| BS6088B(Drop on) | >850 | 0~5 |

| 850~600 | 5~20 | |

| 600~300 | 30~75 | |

| 300~180 | 10~30 | |

| <180 | 0~15 | |

| AASHTOM247 Standard I | >850 | 0 |

| 850~600 | 5~25 | |

| 600~300 | 40~80 | |

| 300~150 | 10~35 | |

| <150 | 0~5 | |

| AASHTOM247 Standard II | >600 | 0 |

| 600~425 | 0~10 | |

| 425~300 | 15~50 | |

| 300~180 | 45~75 | |

| <180 | 0 | |

| China Standard Ⅰ(Intermix) | >850 | 0 |

| 850-600 | 5~30 | |

| 600-300 | 30-80 | |

| 300-106 | 10-40 | |

| <106 | 0-5 | |

| China Standard Ⅱ (Drop on) | >600 | 0 |

| 600-300 | 40-90 | |

| 300-150 | 5-60 | |

| <150 | 0-5 | |

| Ⅰ(for Cold Paint) | >212 | 0 |

| 212-90 | 96-100 | |

| <90 | 0-4 |

Materials:

The raw materials of glass beads are divided into heavy metal glass, recycled glass and pure glass.

- Heavy Metal Glass: The price is the most economical. The reflective effect is very good. However, the heavy metal of the glass will pollute the environment a little.

- Recycled Glass: It is very competitive in price, with the characteristics of good reflection and less damage to the environment, which is widely used in the world.

- Pure Glass: It does not have no any pollution to the environment even though the price is the most expensive. The reflection is very good.

Advantages:

- The glass beads made of the soda-lime silica glass has the good chemical stability, certain mechanical intensity and hardness, free of dark spots and other impurities.

- Does not cause dimensional change to the base material

- Soda Lime glass does not release toxins (no free silica), will not contaminate or leave residue on work pieces, environmentally friendlier than chemical treatments

- Leave even, spherical impressions on blasted part surface

- Low breakdown rate, Lower disposal & maintenance costs

- Suitable for pressure, suction, wet and dry blasting equipment

Factory:

Package Detail: