7 Factors That Affect Road Marking Line Reflectivity

Road marking lines are essential for traffic safety, guiding drivers and pedestrians in all lighting conditions. However, their effectiveness heavily depends on one key quality: reflectivity. High reflectivity ensures visibility during nighttime or adverse weather conditions, while low reflectivity can lead to confusion and increase the risk of accidents. In this article, we explore the main factors that affect the reflectivity of road marking lines, and why maintaining optimal visibility is crucial for road safety.

1. Material Composition of the Marking Paint

The base material used in road marking plays a significant role in determining reflectivity. Common materials include:

Each has different reflective qualities, but thermoplastic paint, often mixed with glass beads, is one of the most effective for high-reflectivity markings.

2. Glass Beads and Their Quality

Glass beads are added to road marking paint to provide retroreflectivity — the ability to reflect light back toward its source (e.g., a vehicle’s headlights). Factors influencing reflectivity from glass beads include:

- Size and roundness: More spherical beads provide better retroreflection.

- Refractive index: Higher index beads reflect more light.

- Application method: Beads can be premixed or dropped on the surface. Drop-on beads tend to reflect more light initially.

Without high-quality glass beads, road markings will appear dull and less visible at night.

3. Application Thickness and Coverage

Proper paint thickness and uniform coverage are essential for good reflectivity. If the paint is too thin or uneven, glass beads may not embed properly, reducing their ability to reflect light. Likewise, insufficient paint may lead to faster wear and degradation.

4. Surface Texture and Road Condition

The condition of the pavement surface can influence how well the road marking bonds and how it reflects light:

- Smooth surfaces may cause poor adhesion of paint and beads.

- Highly porous or textured surfaces can lead to uneven bead distribution.

- Dust, oil, or moisture during application can reduce reflectivity.

Proper surface cleaning and preparation are critical before marking lines.

5. Weather and Environmental Factors

Environmental conditions both during and after application can impact reflectivity:

- Humidity and temperature affect how the paint cures and how well the beads adhere.

- Rain, snow, and UV exposure can degrade markings over time.

- Road debris and tire wear can scratch off beads or obscure lines.

In regions with harsh climates, more durable materials or frequent maintenance may be necessary.

6. Traffic Volume and Wear

Heavy traffic, especially from large trucks or at intersections, leads to faster wear of road markings. Over time, the glass beads get dislodged or crushed, reducing retroreflectivity. High-traffic areas often require reapplication or refreshment of markings more frequently.

7. Age of the Markings

Even with the best materials, road markings lose reflectivity over time due to:

- UV degradation

- Bead loss

- Fading paint

Routine inspection and timely maintenance are required to ensure markings remain visible and effective.

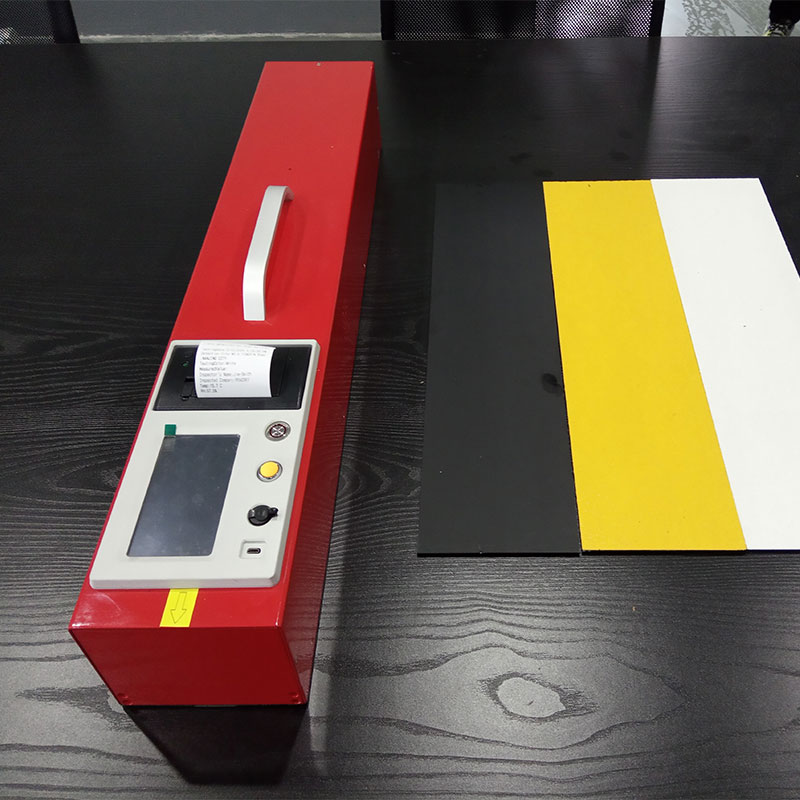

Measure Reflectivity Accurately with a Pavement Marking Retroreflectometer

To ensure road marking lines maintain high visibility over time, it’s essential to measure their retroreflectivity accurately.

Pavement Marking Retroreflectometer RL&QD is a portable field measuring instrument for measuring daytime and nighttime retroreflective brightness. It is used to measure the retroreflective characteristics of road markings. It simulates the brightness of road markings that drivers can see under daytime and nighttime motor vehicle lighting conditions. The measured parameter is the daytime and nighttime retroreflective brightness coefficient, i.e., the RL&QD value.

ROADSKY type pavement marking retroreflectometer (retroreflectometer for road markings) is a portable on-site measuring instrument, used for measuring the retroreflection characteristic of road marking. ROADSKY type instrument is to simulate the brightness of road marking that can be seen by the driver under the illumination of motor vehicles at night, and the measured parameter is the coefficient of retrorefection brightness at night, namely, RL value.

Conclusion

Road marking line reflectivity is not a fixed property—it changes depending on multiple factors, including material quality, environmental exposure, and traffic conditions. To ensure road safety, it’s vital to choose high-quality materials, apply markings correctly, and maintain them regularly. By understanding the factors affecting reflectivity, road authorities and contractors can take proactive steps to keep roads visible and safe, day and night.