What is a Retroreflectometer? What You Need to Know

When it comes to road safety, visibility is everything. Drivers depend on road markings, signs, and reflective surfaces to navigate safely, especially at night or in low-light conditions. But how do engineers and inspectors ensure that these markings meet the required visibility standards? The answer lies in a specialized instrument called a retroreflectometer.

What is a Retroreflectometer?

A retroreflectometer is a precision measuring device used to evaluate the retroreflective properties of materials such as road markings, traffic signs, license plates, and reflective tapes. Retroreflection is the ability of a surface to return light back to its source, which makes markings and signs visible to drivers at night when illuminated by headlights.

In simple terms, a retroreflectometer measures how bright and visible a surface will appear to drivers at night.

Why is Retroreflection Important?

Retroreflective performance is critical for road safety. According to traffic safety studies, clearly visible road markings and signs significantly reduce the risk of accidents. Without proper retroreflection, markings can fade into the background, making it difficult for drivers to stay in their lanes or see warnings in time.

Key benefits of retroreflective measurement include:

- Improved safety: Ensures road users can see signs and markings in low-light conditions.

- Regulatory compliance: Meets government and industry standards for visibility.

- Cost efficiency: Helps maintenance teams prioritize which markings and signs need replacement.

How Does a Retroreflectometer Work?

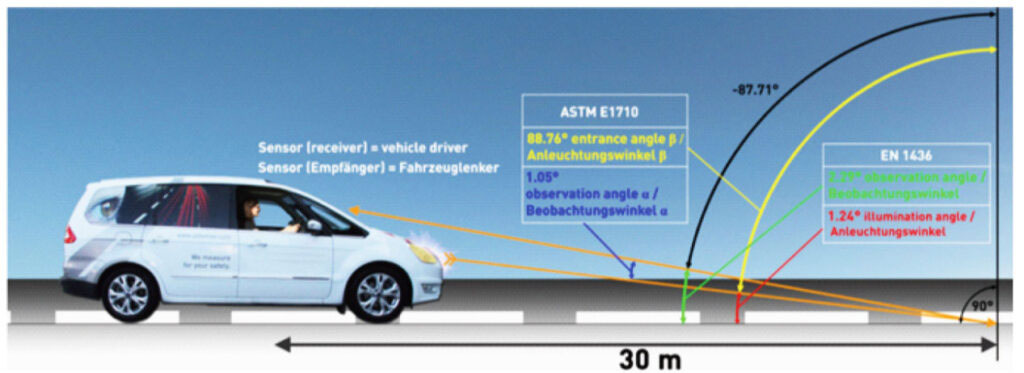

A retroreflectometer simulates the way a vehicle’s headlights illuminate a surface and how much light is returned to the driver’s eyes. It measures retroreflectivity in millicandelas per square meter per lux (mcd/m²/lx).

Applications of Retroreflectometers

Retroreflectometers are widely used in transportation, safety, and quality control industries. Common applications include:

- Road markings: Assessing visibility of lane lines, crosswalks, and edge lines.

- Traffic signs: Ensuring signs meet minimum retroreflectivity requirements.

- Reflective tapes and films: Quality control during manufacturing.

- License plates: Verifying nighttime legibility.

Standards and Regulations

Different regions have established standards for minimum retroreflectivity. For example:

- The Federal Highway Administration (FHWA) in the United States mandates minimum retroreflectivity levels for traffic signs.

- International standards such as ASTM and EN 1436 specify test methods and performance criteria for road markings.

Conclusion

A retroreflectometer plays a vital role in maintaining safe roads by ensuring that markings, signs, and other reflective surfaces remain visible at night. By measuring retroreflectivity accurately, road authorities can extend the life of their assets, enhance driver safety, and comply with global standards.

If your business involves road construction, traffic safety equipment or reflective materials and you are looking for this equipment, you can contact us directly for more information.